- Product name:Servo drived piston (Volumetric) system filling machine

- Model No:AXGZ-SS

- Features:

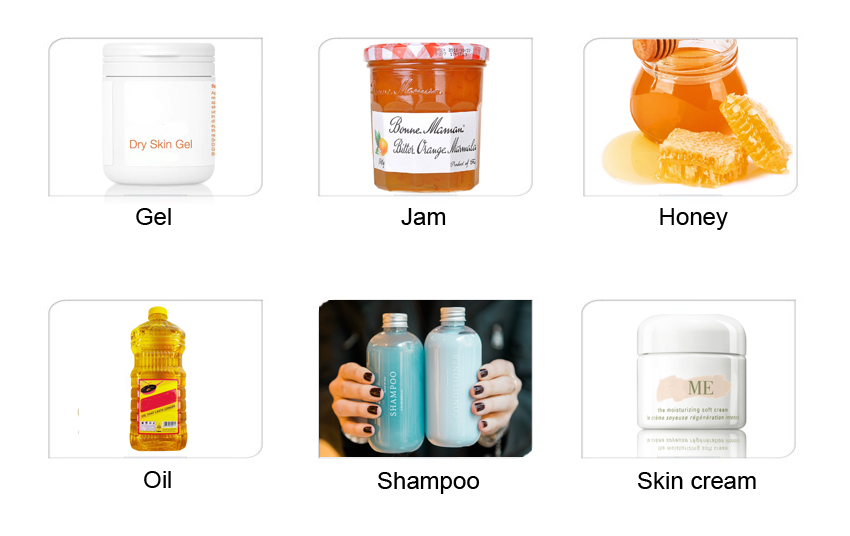

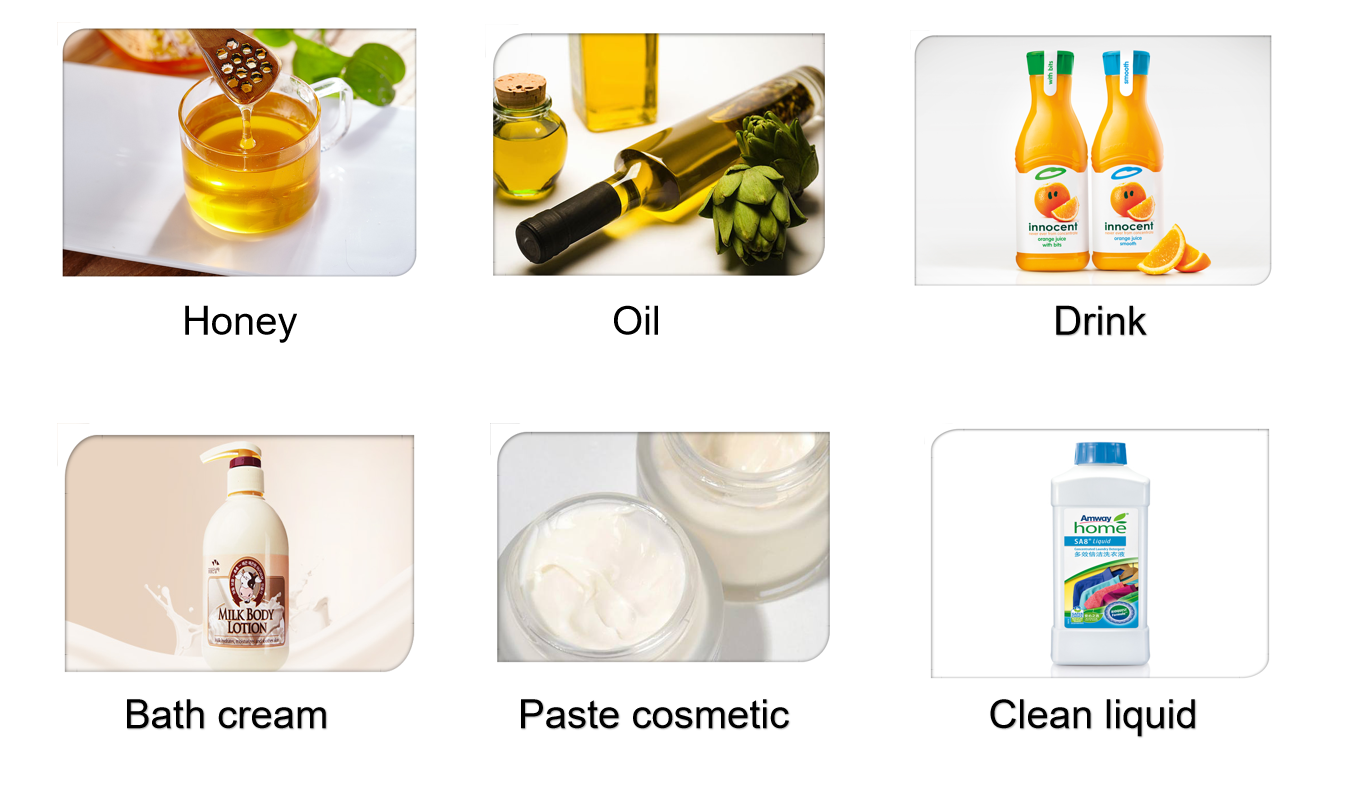

How It Works: The piston is drawn back in its cylinder so that the product is sucked into the cylinder. A rotary valve then changes position so that the product is then pushed out of the nozzle instead of back into the hopper. Application: This type of piston filler is best suited for viscous products that are paste, semi paste, or chunky with large particulates. These piston fillers are built to meet food grade standards and can also handle various chemical applications. Examples: Light oils like olive oil, baby oil, and also shampoo. Heavy sauces, salsas, salad dressings, cosmetic creams, heavy shampoo, gels, and conditioners, paste cleaners and waxes, adhesives, heavy oils and lubricants. Advantages: For most users, this low-cost traditional technology is easy to understand and operate. Fast fill rates are achievable with fairly thick products.

Product specifications

Main parameters of the machine

Data sheets

Details

Name and model

AXGZ-SS-4B

AXGZ-SS-6B

AXGZ-SS-8B

AXGZ-SS-12B

Max filling speed (pcs/hour)

1500~2500

2400~3000

2800~3600

4000~4500

Power (KW)

2.0

2.0

2.0

3.0

Net weight (Kgs)

800

850

900

1200

Applicable bottle diameter size

Φ20 ≤D≤Φ100mm

Applicable bottle height size

30≤H≤300 mm

Filling dose

100~ 1000ml

Filling accuracy

±1%

Voltage

AC220V, single phase, 50/60HZ

Working pressure

0.6MP

Air consumption

600L one hour

Machine size(L*W*H)

2000*1200*2250mm

Machine direction

From left to right

Operation process

Put products on conveyer—>Block bottles—> sensor count the empty bottles—> bottles come into the filling station —>lock bottles —>starting filling —> filling finished —> loose Block bottles—> Output bottles