- Product name:4 Nozzles Automatic Pump Liquid Filling Machine

- Model No:AXGZ-RR

- Features:

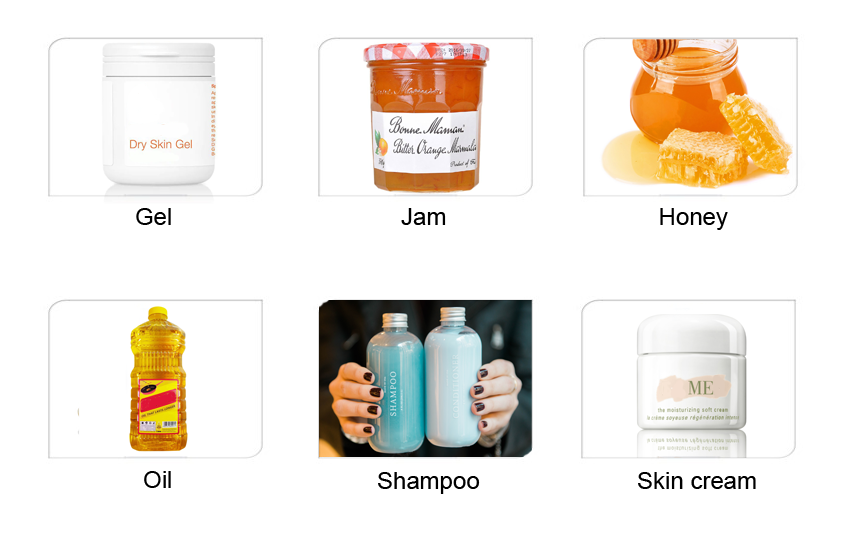

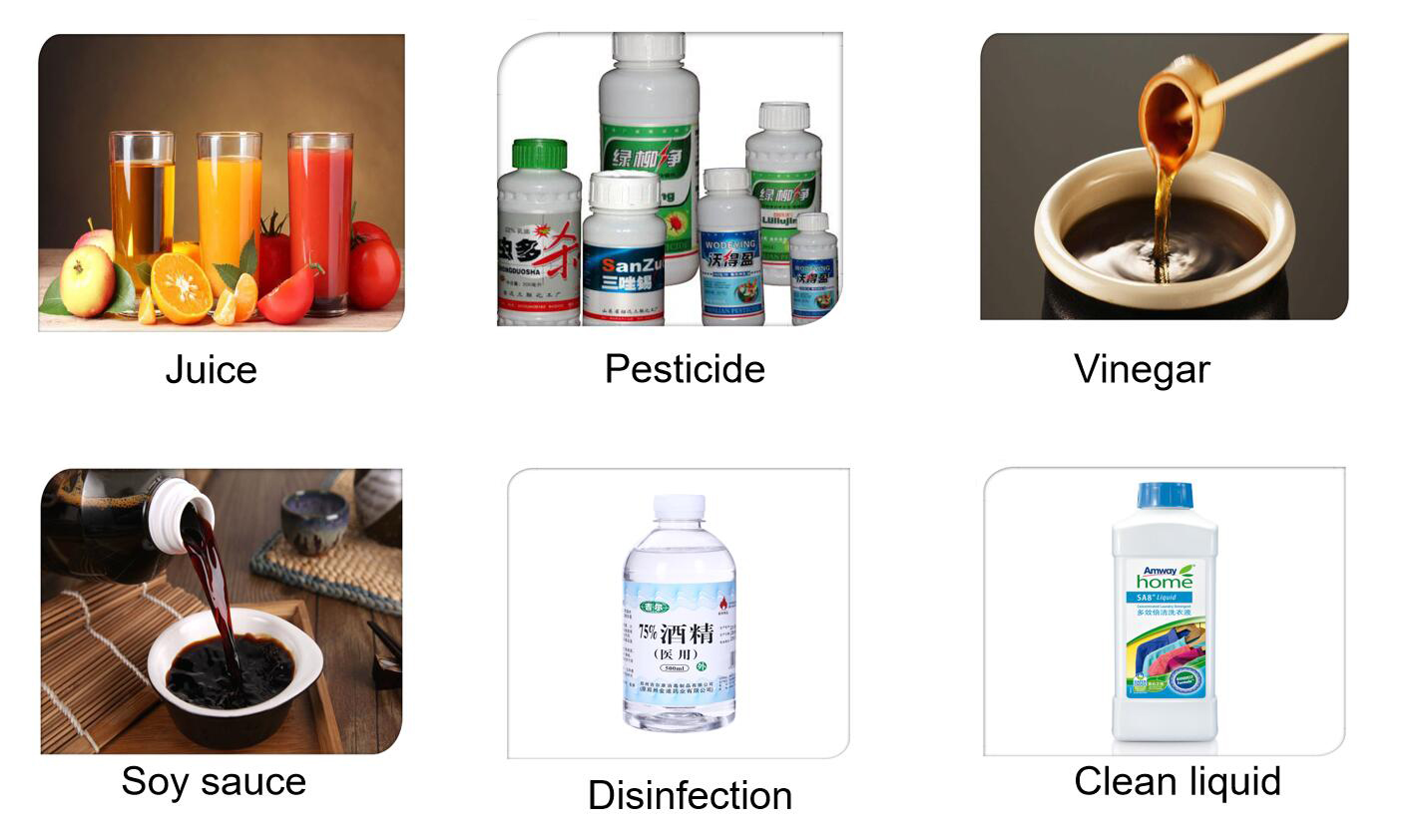

Product Description Our machines have especially been designed to fit the needs of the cosmetics, the pharmaceutical, and the chemical and, the food industry. One-stop supplier for bottle unscrambling, filling, capping and labeling System Covers output ranges from approx. 1.500 up to approx. 4.500 bottles per hour Standard program structure and user-friendly interface Consistent application of the Puck System Safe and cautious bottle transport in Pucks High functional reliability and efficiency Rapid format change-over times Minimal format costs Short delivery times Seal of quality “Germany” The following products can be processed by our flexible filling lines depending on their version: Bottles from approx. 20 up to 1.000 ml Highly liquid up to viscous or foaming products 2-phase products 2-color products Roll-on deodorant Screw- and press-on caps Orientation caps Plugs, droppers, roll-on ball fitments Oblique seat caps Dosing- and spray-pumps Small trigger pumps Tottles Choose the filling method according to the filling material Choose the capping machine according to the customer's cap design Choose the labeling method according to the shape of the bottle

Product specifications

Characters:

|

Power supply |

AC 220V; 50HZ (or according to client voltage requirement) |

|

Power |

0.7 KW |

|

Filling volume range |

50ml ~ 1000m |

|

Production Capacity |

when filling1000ml,≤ 800bottle/hour |

|

Error ;Range |

1%Max |

|

Container size Range |

High: 80mm~280mm ; Diameter: 80mm~200mm |

|

Pneumatic (air-operated) source |

0.55Mpa~0.65Mpa |

|

Machine Weight |

280kg |

|

Machine Dimension (L x W x H) |

4500mm x 1500mm x 2000mm |